When Eric Black, the owner of the LA Unplugged, sends his three installers to build a Wi-Fi hot spot or a wireless local area network (WLAN) of Wi-Fi facilities to cover a more extensive area, they take along kits of Unidabt™ cable connector adapters.

“We design, engineer and install wireless systems. In Hermosa Beach, California, we built a wireless system that covers 20 percent of the city. It has free access and fairly high-speed Internet connections equivalent to three T1s, or about 6Mb,” Black said.

Wi-Fi allows computers to use the Internet without wired connections. But at the very least the wireless transmitters and receivers that enable the Wi-Fi nodes require cables to connect them with various types of antennas that emit and receive signals to and from the computer.

The high frequencies involved mean relatively higher signal attenuation in cables, so using cables at a minimum length improves overall system performance. Yet it wastes time when technicians have to install connectors in the field or sort through a large inventory of prefabricated cable-connector combinations.

What multiplies the problem is the Wi-Fi equipment manufacturers use a variety of input and output connector sockets on their black boxes because no standard has emerged. Also, using a unique connector style helps to prevent inadvertent connection with devices that could damage the Wi-Fi equipment.

As a result, technicians face a variety of socket styles, size and threading directions that can stand in the way of a speedier installation. (Some equipment manufacturers us sockets with reverse threads.)

Black explained that LA Unplugged installs hot spots in municipalities, malls and shopping centers using a fairly limited set of radio equipment and a variety of antennas, each with a different connector.

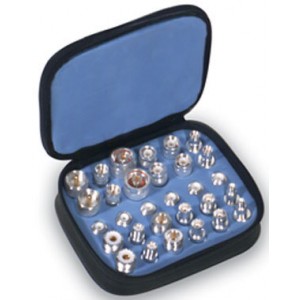

“We have to create new pigtails every day. We do that to adapt to new antenna connections. We use the RFA-4024-WIFI 30 piece Wi-Fi Unidapt™ kit. That has really served us well, Black said.

“One time, we used almost every connector in the kit, which is six times 4, or 24 connectors. It’s been a real lifesaver in a lot of ways. It would be a nightmare to have to make and crimp or solder and create the pigtails every time we test a new antenna,” he said.

Black’s three installers share one kit plus several extra adapter connectors and a cable tester.

Adapters come into play at several stages during Wi-Fi hot spot construction.

During a site survey, the adapters allow technicians to try out various antennas and measure results with different radios in whichever spectrum is used, including 802.11 (a), (b) or (g). Then technicians use adapters again during actual installation as antennas are tested once again to make sure they meet the engineered coverage specifications.

The kit then is used with Unicable™ to build the cable assemblies, which later are replaced with permanent pigtails made from connecting the antennas to the radios. Adapters also are used with the coaxial cable tester to test the permanent cables.

“We like to make a lot of tweaks,” Black said. “We have the kit so that allows us to do things we wouldn’t bother with otherwise. We are able to try things out.”

Black attributed his company’s success in winning municipal bids at almost the same price points as competitors to his organization’s experience, and “we had a really good design.”

Unexpectedly, the Unidapt™ Universal Adapter Kit draws customer attention all by itself.

“Customers think this is the coolest thing they’ve seen. Their faces light up when they see it for the first time. They see a form-follows-function kind of beauty. I’ve had comments as though it were a piece of art, all this stainless steel and the way it’s positioned in the foam-lined zipper case. Even city government officials are taken by the Unidapt™ Kit’s stainless steel as though it were some kind of work of art,” Black said.

Black said that using the kit saves a lot of time.

“We’ve never calculated it,” he said, “but out of every six hours, it probably saves an hour. We’ve had the kit since it came out in February 2004, which is when our business started. We have a lot of clients, and we’ve always had the kit. We haven’t done that much work without it.”

On the opposite side of the country, Bruce Marcus of Marcus Communication & Electrics in Manchester, Connecticut, has used the adapters for many years.

“I have every one they make, including the supper big one (the 74-piece RFA-4022),” Marcus said.

“My technicians carry at lease two on service calls. The 36-piece kit, everyone has two. The master kit, I keep one with me, and I must have two of the next larger kits in my lab at the house. And our technicians who work on antenna combiners and who conduct field testing carry the big gray ones,” Marcus said.

Although the company’s business is concentrated in New England, Marcus himself travels widely. He consults throughout the country and sometimes overseas.

“FedEx can go everywhere, so do my RF Adapters,” Marcus said,

He said that while he has found every type of connector possible in use at various radio repeater and Wi-Fi installations, including reverse-threaded female SMA connectors on cables. “Without the Unidapt™ kit, we couldn’t have put them on the air,” he said, “I would have driven myself crazy.”

Marcus said one problem is to remember to take the adapter out, once the facility is up and operating.

“When the adapters first became available, I thought it was a clever idea. The supplier has a cable with female Unidapt™ on it, so you don’t need to put the end of the gender on the cable. It’s a blue cable that stands out. I carry it all the time. You don’t need the immediate end, you only need to put the face on the cable as opposed to adapting a ready-made cable and having to put a male-female connector on it to adapt. It’s good for functional testing in the field,” Marcus said.

Marcus said that the adapter’s mechanical integrity and signal loss characteristics are equal to made-up adapters.

“I would not leave them in permanently because they are screwed in and can come loose. For emergency and testing, they’re perfect because you have them right now with you,” he said.

Some of the kits have two each of every adapter, but Marcus said sometimes four adapters are required, which is why he equips each technician with two of the smaller kits or the bigger kit.

“I have the giant kit for when we’re traveling long distances. It has 7/16 DIN adapters, and the big kit has AMEX for connecting the circuits inside portables and on circuit boards and microwave equipment. They’re smaller than an SMA connector. They have the MX series, a tiny connector the size of a pencil lead,” Marcus said.

He explained that a lot of manufacturers, including American and Japanese companies use the small connectors as interconnectors on circuit boards.

“If you need to make a low-level measurement on a circuit board or inside portables and microwave equipment and you don’t have the tiny adapters, you’re lost. The connectors look like sub-miniature BNC barrel connectors,” Marcus said.