Throughout any Distributed Antenna System (DAS) there are a variety of RF connectors used to join the cabling to the component interface. While many of the common connector types will work in a DAS environment, some are better suited than others when it comes to reducing interference. PIM is a major cause of signal degradation in DAS and choosing the right connector type to help reduce PIM is imperative.

Which Connector Type is best for DAS?

For DAS, you will want to use low PIM connectors and depending on the type of DAS some connectors will perform better than others. In some cases, the DAS architecture or the components being installed will require you to use one connector over another. Most common connector types will perform well within the lower frequency bands when properly installed but it is when you have a DAS operating in the higher frequency bands that you begin to discover PIM issues.

The key is to choose a connector that will perform well in both low and high frequency bands. This will allow you to use the same connector type throughout the entire DAS system without fear of having problems later down the road should additional frequencies be used.

How Connectors Cause PIM

PIM is new frequencies generated by the transmit signals when they encounter non-linear junctions or materials in the RF path. To keep it simple PIM is interference. When this interference (PIM) is generated it falls over into the uplink band which increases the noise floor and interferes with the mobile device signals leading to access failures, slower data rates and dropped calls.

-

Connectors can cause PIM in a variety of ways:

- Poor Cable Termination

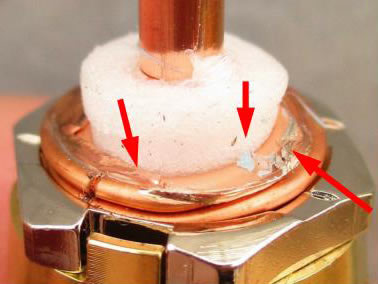

- Damaged or Poorly made Connector – broken or cracked solder, nickel plating, shipping damage

- Loose Connector – not properly torqued

- Over-torqued or broken connector

- Metal flakes inside connector – flakes appear with each mating cycle. Worse if touching conductors.

- Metal flakes inside cable

Of the common connector types used in DAS, test results have shown that Type N connectors do not perform well when testing PIM at the higher frequency bands.

PIM Testing – Connector Results*

Testing results using 700MHz, 850 MHz, 1900 MHz, 2600 MHz – PIM was introduced to see how the connectors performed across a range of frequency bands. The connectors were subject to the same test configuration to compare results.

| Connector Type | 700 MHz (dBm) | 850 MHz (dBm) | 1900 MHz (dBm) | 2600 MHz (dBm) | Delta (dBm) |

|---|---|---|---|---|---|

| N Type | -100 | -95 | -80 | -72 | 28 |

| 7-16 | -118 | -112 | -107 | -97 | 31 |

| 4.1-9.5 | -121 | -121 | -112 | -102 | 19 |

| 4.3-10 | -129 | -124 | -127 | -120 | 9 |

N Type – average results – if connector loosens from vibration or incorrect torque the connector will fail PIM miserably – not a great performer in the lower frequency bands but performs worse at higher frequency bands – No middle ground with N Type – PIM was either very good or very bad.

7-16 DIN – similar results to the Type N connector but did perform slightly better. Like the Type N connector, the 7-16 DIN performed worse at higher frequency bands.

4.1-9.5 – better PIM results than the N or 7-16 DIN connectors. Very little PIM at lower frequency bands and only performed slightly worse at the 1900 and 2600 bands.

4.3-10 – (push-pull connector) Very good results – PIM was flat across all frequency bands. This seems to be a great connector for use in DAS systems – using the push pull connector there is no way to create an un-torqued connection and virtually eliminates the metal flakes that are created when mating and un-mating other connectors.

Connector Summary

Loose connector PIM is worse at higher frequencies – the 4.3-10 connector performed the most consistently of all connectors across all frequency bands – the 4.3-10 connector appears to be the best choice for use in a DAS environment.

No matter which connector is chosen it is important to ensure that the connector is properly terminated onto the cable and the connector is properly torqued when installed on the interface. Even a slight loosening of the connector (through vibration) will cause PIM to increase significantly.

*Anritsu test results 2015