Application

Fiber Optic connectors and cables are present in nearly every communications project that we might sell into, be it a DAS installation or a Base Station with wireless backhaul, you can be certain that fiber jumpers and cabling are being used somewhere in that network. Having a general understanding of fiber optics and the different fiber and connector types that are available will allow you to have a more productive conversation with your customer.

Some Fiber Basics: Transmitting Signals with Light

Digital Light Signals – Lasers inside the equipment generate the light that the fiber cables carry.

Just as copper cables use pulses of electricity to carry signals across a copy wire, Fiber Optic cable uses pulses of light. For digital communication we transmit in ones and zeros. For copper, the difference between a one and a zero is a change or variation in the electric pulse within a certain acceptable range. To keep it really simple, the presence of a pulse at a certain time is a one (1) and the absence of a pulse is a zero (0). The same principle is used for fiber optics only instead of electrical pulses we use pulses of light. A laser source inside the hardware is used to turn the light on and off. For Fiber Optics, again keeping it as simple as possible, the presence of a light pulse at a certain time is a one (1) while the absence of a light pulse is a zero (0). To further simplify it – light on = 1, light off = 0.

The Optical Core – a glass tube (core) propagates the light signals through the fiber cable.

Glass is inherently reflective and is a perfect medium for transporting light. Because of this, fiber optic cables use a glass tube (core) in their center to transport the light pulses generated by the lasers. These light pulses travel (propagate) down the glass core by reflecting (bouncing) off of the sides. Other than the original laser, the transported signal does not require any power whatsoever, the light reflecting inside the core is what carries the signal through the fiber cable. The signal does weaken the farther it travels and will eventually need to be regenerated but not before it has traveled quite a long way. Some fiber optic cables can carry signals for 60 miles or more before they need regenerated.

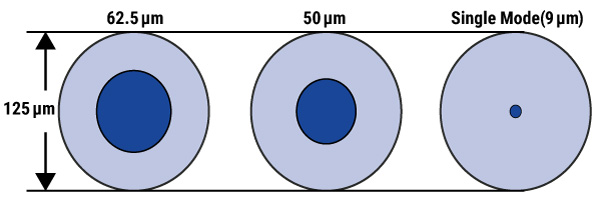

Relative Size Comparison

The center of the fiber, or the Core, plays a big role in the quality and distance the signal can travel through the fiber. Core size is a big factor in how far the signal will travel. In general, the smaller the core the farther the optical signal (light pulse) will go before it needs regenerated.

Later we will get into a bit more detail on Single Mode and Multi-mode Fiber cables but for now understand that Single Mode Fiber has a much smaller core than Multimode Fiber. This smaller core keeps the reflections tighter and on a more direct path thus allowing the optical signal to travel farther.

Standard Fiber Core Sizes

- Multimode Fiber Core Size: 50um and 62.5um

- Single Mode Fiber Core Size: 8 – 9um

Note: Core measurement is in microns (um)

In General, Single Mode (SM) fiber is used for long distances or higher bandwidth needs and uses a laser has its light source while Multimode (MM) Fiber uses an LED as its light source and is used for short distances or less bandwidth intensive applications.

Wavelengths – The light that is traveling through the core

Without getting into too much detail we need to talk about wavelengths. Just like copper cables carry different RF frequencies, fiber cable carries different frequencies of light or wavelengths. To keep it simple, think of the wavelength as a color of light and each color of light takes its own path down the core of the fiber and will not interfere with the other colors of light that might be traveling down the same fiber. (Basically, what we have just described is wavelength division multiplexing WDM or DWDM)

The light source determines the wavelength. Lasers can be tuned to send specific wavelengths down the fiber core. And since each wavelength takes a different path down the core of the fiber, some fiber types are better suited for some wavelengths. As you will see, Multimode Fiber transports light signals at different wavelengths than Single Mode Fiber.

Standard Fiber Wavelengths

- Multimode Fiber: 850nm and 1300nm

- Single Mode Fiber: 1310nm and 1550nm

Note: Wavelength is measured in nanometers

Fiber Optic Cable Types

Typically customers will ask for either multimode or single mode fiber cable. They may be able to give you some specifics but not always. They may rely on you to decide the exact type of fiber they need. Every now and then you may have a more technical customer that asks for Fiber cable but gives you a specific type like OM3 fiber. Well what does that mean? What is OM3 or OM4 Fiber?

This section will review the more technical naming conventions and specifications for both Multimode and Single Mode Fiber.

Multimode Fibers – OM1, OM2, OM3, OM4 and OM5

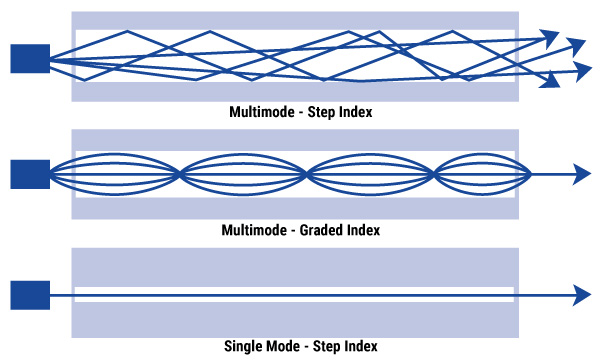

Multimode fibers are identified by the OM (optical mode) designation and their specifications are outlined by the ISO/IEC 11801 standard. Multimode cable disperses the light into multiple paths as it travels down the core. This allows for higher bandwidth over short to medium distances. However, on longer cable runs, multiple paths of light can cause distortion at the receiving end, resulting in an unclear and incomplete data transmission. For this reason, Multimode is generally only used for short distance applications like data centers.

Types of Multimode Fiber Cable and Specifications

OM1

- Jacket Color – Orange

- Core Size – 62.5um

- Data Rate – 1Gb @ 850nm wavelength

- Distance – Up to 300 meters

- Application – Short-haul networks, Local Area Networks(LANs) & private networks

OM2

- Jacket Color – Orange

- Core Size – 50um

- Data Rate – 1Gb @ 850nm wavelength

- Distance – Up to 600 meters

- Application – Short-haul networks, Local Area Networks(LANs) & private networks

- Generally used for shorter distances. Has twice the distance capacity has OM1

OM3 – Laser-Optimized Multimode

- Jacket Color – Aqua

- Core Size – 50um

- Data Rate – 10Gb @ 850nm wavelength

- Distance – Up to 300 meters

- Uses fewer modes of light, enabling increased speeds

- Able to run 40GB or 100GB up to 100 meters utilizing an MPO connector

- Application – Larger Private Networks

OM4 – Laser Optimized Multimode

- Jacket Color – Aqua

- Core Size – 50um

- Data Rate – 10G @ 850nm wavelength

- Distance – Up to 550 meters

- Able to run 100GB up to 150 meters utilizing an MPO connector

- Application – High-Speed Networks, Data Centers, Financial Centers and Corporate Campuses

OM5 – The latest and greatest in Multimode Fiber

- Jacket Color – Lime Green

- Fully compatible and can mate with OM3 and OM4 cabling

- Utilizes a wider range of wavelengths between 850nm and 953nm

- Designed to support Short Wavelength Division Multiplexing (SWDM)

- Can Transmit 40 Gb/s and 100 Gb/s

- Application – High-speed Networks and Data Centers that require greater link distances and higher speeds.

Multimode Fiber Summary

Multimode fiber has come a long way in 30 years. It has evolved with the growing demand for more speed. Since OM1 and OM2 fiber could not support the higher speeds, OM3 and OM4 became the main choice for multimode fiber to support 25G, 40G and 100G Ethernet. With even greater demands on the horizon, OM5 was developed to extend the benefits of multimode fiber in data centers.

Single Mode Fibers – OS1 and OS2

Single Mode fibers are identified by the designation OS or Optical Single-mode Fiber. Single Mode cable has a much smaller core (8-9um) than multimode cable and uses a single path (mode) to carry the light. The main difference between single mode OS1 and OS2 is cable construction rather than optical specifications. OS1 type cable uses a tight buffered construction while OS2 is a loose tube or blown cable construction.

OS1 Single Mode Tight Buffered Cable

Each fiber has its own protective two-layer coating (color-coded for identification). One layer is plastic and the other is waterproof acrylate. The tight buffer allows for a smaller, lighter weight cable that is more flexible and crush resistant than Loose Tube. Installation is easier as there is no gel to clean up and no fan out kit required for connector termination.

Application: (Indoor Use) – moderate distance telco local loops, LANs and point-to-point links in cities, buildings, factories, office parks or campuses. OS1 can support speeds up to 10G and distances up to about 10km (6 miles).

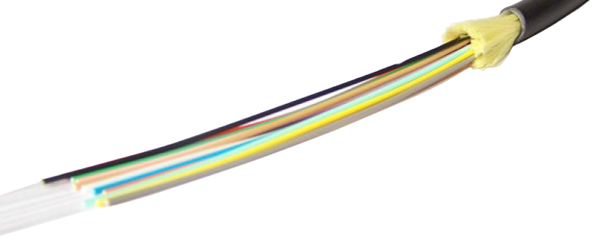

OS2 Single Mode Loose Tube Cable

All fibers are essentially bare other than their outer coating. Each fiber has a colored coating for identification. Other than this coating the fiber “floats” within a rugged, abrasion resistant, oversized tube usually filled with optical gel which protects the fibers from moisture. Connector termination requires a fan out kit.

Application: (Outdoor Use) high fiber count, long distance telco backbone and backhaul lines, direct bury applications along streets and railroads. OS2 can support speeds up to 100G and distances up to 200km (124 miles).

Single Mode Fiber Summary

Single Mode jacket color is typically yellow for jumpers but you may see a variety of colors depending on the application and the outer jacket type.

Single mode fiber is the standard choice for high data rates or long distance spans and can carry signals at much higher speeds than multimode fibers with less signal attenuation and external interference. It offers many advantages over multimode fiber and is an effective way to future proof your network cabling infrastructure.

Keeping things Clean

The most common problem we see with any fiber network is a dirty connector. Small particles of dirt and dust can partially block the light signal causing degradation. It is important to keep the connectors clean and free of dirt.

The best way to clean them is with a fiber optic cleaning box. This is a small handheld plastic box housing fiber optic cleaning tape. These are disposable boxes that typically can clean about 500 connectors before needed refilled.

The best way to clean them is with a fiber optic cleaning box. This is a small handheld plastic box housing fiber optic cleaning tape. These are disposable boxes that typically can clean about 500 connectors before needed refilled.

A good fiber optic cleaning kit will contain everything you contain everything you need to keep your fiber connectors clean.

A couple other tools that are extremely helpful when testing and troubleshooting fiber are a fiber inspection scope and a visual fault locator.

The fiber inspection scope allows you to inspect the fiber connector ends for dirt or any scratches or impairments that might be blocking the light from passing through the connector. A visual fault locator of VFL, sends a visible red laser through the fiber helping you identify if the fiber is cracked or exceeding the maximum bend radius.

Keeping the fiber connector ends clean is the single most important thing you can do to ensure your signal remains in good working order. While this article is not about fiber cleaning, we thought it was important enough to mention here. We will add an article focused on fiber optic cleaning soon.