Intermod and connectors: Silver plate beats nickel

When connectors made entirely of non-ferromagnetic materials are used, they do not have to become the weak link in a communications system, causing harmful and hard-to-find intermod interference.

Intermod (Intermodulation)

The simple mention of the word is dreadful to most two-way radio communications technicians. Intermod refers to intermodulation interference, a mixture of two or more signals that results in one or more unwanted signals disrupting reception.

The cause usually is found in transmitters, receivers, transmitting combiners, receiver multicouplers, antenna systems and dissimilar metal junctions near transmitters. Few technicians think to examine coaxial connectors used with-in the system.

The introduction of 800MHz and 900MHz trunked and cellular communications systems that combine multiple transmitters into one antenna has created the potential for a widespread inter-mod problem that should be solved be-fore installing a system. Intermod that can be generated with-in an active circuit, such as a receiver, can be generated within passive system components.

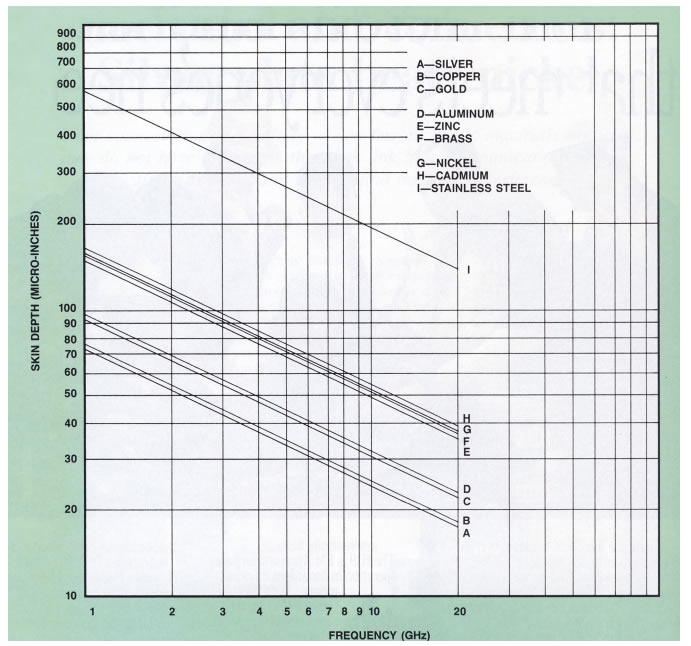

A surprising fact: At frequencies near 800MHz and 900MHz (1GHz, on the graph), most of the radio energy travels within 80 micro-inches of a copper conductor’s surface. To put this in perspective, a human hair measures 3,000 to 5,000 micro-inches thick.

Any passive component that exhibits a non-linear behavior, including a simple coaxial transmission line, can contribute to the problem. Understanding how intermod can be generated within a transmission line begins by looking at its electrical and mechanical properties. A properly designed connector is nothing more than an extension of the transmission line. It exhibits the same electrical properties, and it can be as important in the initial system design as the selection of the antenna, combiner and transmission line.

When carried by a conductor, radio energy travels along its surface. The higher the frequency, the more pronounced the skin effect. Figure 1 above shows a surprising fact: At frequencies near 800MHz and 900MHz (1 GHz, on the graph), most of the radio energy travels within 80 micro-inches of a copper conductor’s surface. To put this in perspective, a human hair measures 3,000 to 5,000 micro-inches thick. The skin depth for radio energy carried by a conductor is determined by a number of factors besides the radio frequency, including conductivity and permeability.

Conductivity remains constant for a given metal, but permeability varies if the metal is susceptible to magnetism, as are iron-based materials commonly called ferromagnetic materials. When an ac signal is applied to a ferromagnetic conductor, the magnetic field associated with the signal varies in proportion to the current. Variations in the magnetic field cause the conductor’s skin depth to vary. The variance creates a non-linear circuit that can generate intermod. Perhaps this fact seems insignificant because modern coaxial cable is made of copper, silver or aluminumall non ferromagnetic materials. But consider the construction of connectors.

The manufacture of connectors is driven by economics, as well as by mechanical and electrical performance considerations. Most modern connectors are made from a base material, and then plated. This construction provides a satisfactory combination of mechanical properties and electrical performance. The preferred base material is brass, a copper alloy composed of 65% to 70% copper and the remainder is zinc. The base metal may be plated by one of a number of materials. Nickel commonly is used because it costs little, resists tarnish and wears well. But nickel is a ferromagnetic material that is susceptible to variable skin depth and the corresponding nonlinear performance. Intermod caused by nickel-plated connectors has been found to be such a problem that in 1975, a report by a naval research laboratory investigating passive component non-linearity problems in satellite communications systems stated that “their immediate removal is strongly

recommended.” The satellite communications system in question operated in the 240MHz-to-320MHz range.

The report recommended revising the military standard of connector manufacture, MIL-C39012B, to exclude nickel-plated connectors. Subsequently, the standard was so revised. Many connector manufacturers continue to offer nickel-plated connectors because the alternative

nonferromagnetic plating material, silver, is more expensive, is difficult to package to avoid tarnishing while on the shelf, and is prone to tarnishing once installed. The slightly higher cost and the tarnish that might appear on silver-plated connectors should not deter communications systems designers and technicians from specifying them in their installation. When connectors made entirely of nonferromagnetic materials are used, they do not have to become the weak link in a communications system, causing harmful and hard-to-find intermod interference